PrecisionScan

Giá bán: Liên hệ

Hãng sản xuất: NDC Technologies

Danh mục: Thiết bị trong dây chuyền sản xuất

Nhà cung cấp: Anh Nghi Son

Xuất sứ:

Bảo hành: 0

PrecisionScan

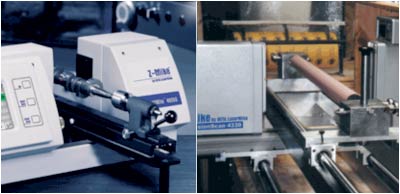

Precision Measurement Heads

Beta LaserMike has a complete line of Z-Mike scanning laser gauges for applications where a bench-top solution is not required. This family of gauges is available in a wide choice of measurement ranges, accuracies, and sizes to provide the perfect product to fit your measurement needs. Beta LaserMike offers two series:

- 4000 Series High-Precision Gauges for tighter tolerance applications

- 2000 Series General Purpose Gauges where tight tolerances are not as critical

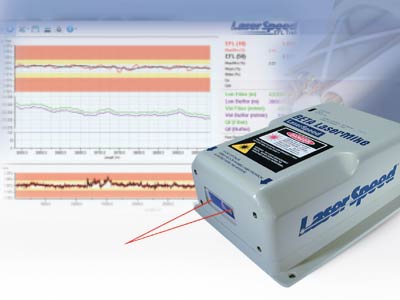

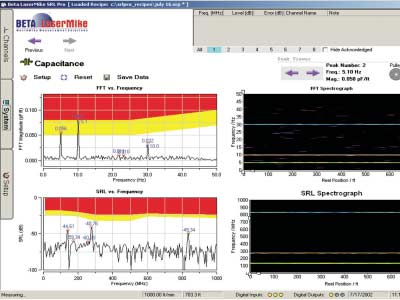

The PrecisionScan gauges can be interfaced with the Beta LaserMike PrecisionPro dimensional

measurement processors for optimum production control.

A variety of Modular Fixtures are available for any gauging need to properly

hold workpieces.

Measure parts with the highest accuracy. (Click image to view)

Patented optical design and edge-sensing electronics provide high-precision measurements. Auto-compensation features maintain accuracy throughout the measurement range and adjust for thermal expansion outside laboratory environments.

Get reliable measurements from run to run.

Non-contact measurement technique provides the same level of accuracy, regardless of operator. Tolerance checking alerts operators of out-of-tolerance conditions. Mounting fixtures ensure the test piece is always properly presented to the gauge.

Easy-to-use features.

The PrecisionScan gauges can be interfaced with the Beta LaserMike PrecisionPro dimensional measurement processors for optimun production control. These processors are easy to learn and use.

The PrecisionScan gauges are proven performers in a wide range of industries. These gauges are designed to provide accurate and repeatable measurements of product samples. Industry applications include:

- Small Motor Crankshafts

- Camshaft Lobes

- Crankshaft Bearings

- Cutting Tools

- In-line Cordless Drill Shafts

- Center-less Grinding

- Bar Polishing

- Pin Gauges

- Catheters & Guide Wires

- Meat Casings

- Copier and Rubber Print Rollers

- Can Punches and Dies

- Battery Cans

- ID & OD of Steel Tubes Reducing Dies and Mandrels

- Cold Metal Tubes

- Hot Products

- And more...

- The following technical information provides a range of performance data across all models.

For specific product details to meet your unique application needs, please refer to our data sheets. -

- Measurement Range: 2.5 to 330 mm (0.01 to 13.0 in.)

- Repeatability: to ±0.3 μm (±0.000010 in.)

- Linearity: as low as ±0.8 μm (±0.000030 in.)