Wire Preheating Systems

Giá bán: Liên hệ

Hãng sản xuất: NDC Technologies

Danh mục: Thiết bị trong dây chuyền sản xuất

Nhà cung cấp: Anh Nghi Son

Xuất sứ:

Bảo hành: 0

Wire Preheating Systems

In-Process Wire Heating

Preheaters from Beta LaserMike provide uniform, in-process wire heating to eliminate insulation voids in primary cables. When a wire is preheated for only fractions of a second by a low frequency (50/60 Hz) heat cycle, the heat is unevenly applied to the wire, resulting in hot and cold spots. When high frequency preheating is used, more heat cycles are applied to the wire, ensuring more consistent heating all along the length of the wire. For this reason, all Beta LaserMike Preheaters use high frequency heating. Beta LaserMike offers a full range of models to meet your unique wire preheating needs.

Industry leading safety features.

Wire break detection, current overload sensors, and a concealed wire path behind the electrically locked door provide peace-of-mind safety to your equipment, process, and personnel.

Flexible temperature interface

External temperature controller interface allows compensation for low-speed applications and varying input temperatures.

Efficient power control.

All preheater components are carefully designed to ensure that power losses are minimized and all input power is used to heat the wire.

Preheaters from Beta LaserMike are proven performers in a wide range of wire and cable industries. These gauges are designed to effectively eliminate cable insulation voids with the highest assurance. Industry applications include:

- Communication cable (i.e., coaxial, CATV, etc.)

- Power cable

- Building cable

- Specialty cable

- And more...

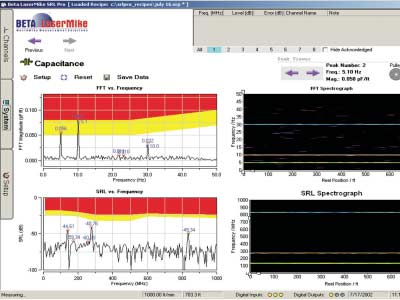

- The following technical information provides a range of performance data across all models.

For specific product details to meet your unique application needs, please refer to our data sheets. -

- OD Range: 0.28 – 2.8 mm (0.01 – 0.11 in.)

- Max Line Speed: up to 2500 m/min. (8200 ft/min.)

- Pulley Size: up to 2 x 280 mm (2.11 in.) Check data sheet for size.

- Power Output: 8 – 16 kVA

- Max Loop Voltage: 17 – 40 V

- Max Wire Temperature: 370 – 750° F (190 – 400° C) Check data sheet for temperature.