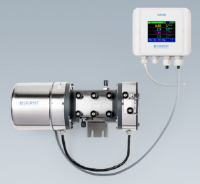

VisGuard OMD Oil Mist Detector

Giá bán: Liên hệ

Hãng sản xuất: Photometer VietNam

Danh mục: Thiết bị đo lường & Kiểm tra

Nhà cung cấp: Anh Nghi Son

Xuất sứ:

- Continuous monitoring of oil mist concentration using scattered light principle

- Fully complying with the latest IMO code of practice for atmospheric oil mist detectors

- Easy to service, high sensitivity, stability and accuracy

- Easy to install, flexible system configuration

- Easy calibration check with checking rod

- A special sample flow concept entirely eliminates the danger of flow cell contamination

- Operation via local control unit or central multi-channel control unit

- Up to 40 measuring points possible

- Dual-beam method

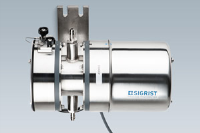

- Option: Installation in stainless steel cabinet 1.4301 IP 55 with 2 doors and 1 window

The VisGuard measures the scattered light intensity of a sample drawn into the instrument. Filtered purge air is fed through the flow cell, thus enveloping the sample in a protective shroud of clean air. This effectively keeps the optics clean. Oil dust in the sample can be detected early to help preventing from further incidents.

|

Nominal range |

0 .. 100 PLA (Polystyrol-Latex-Aerosols) |

|

Scale ranges |

0..0.1 / 0..0.3 / 0..1 / 0..3 / 0..10 / 0..30 / 0..100 PLA |

|

Protection |

IP65 |

|

Sample temperature |

-20 .. +50 °C |

|

Sample pressure |

max. ±3'000 Pa (±30 mbar) |

|

Interfaces |

RS232, Modbus, Profibus DP |

|

Ambient environment |

Temperature range -20 .. +50°C |

|

Maximum service altitude |

3,000 m above sea level |

|

Power supply |

85 .. 264 V / 47 .. 440 Hz |

|

Number of sampling points |

1 .. 40 |