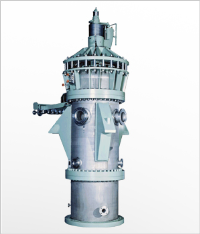

PTM Decanter ( Screen Bowl )

Giá bán: Liên hệ

Hãng sản xuất: Tomoe Vietnam

Danh mục: Máy móc & Hệ thống

Nhà cung cấp: Anh Nghi Son

Xuất sứ:

Bảo hành: 12

Continuous Sedimentation and Filtration

Description

PTM Decanters are employed by the chemical, electric power and mining industries to dewater and rinse paraxylene, ammonium sulfide, gypsum and ores.

Its BPA (Bis phenol-A.) dewatering/rinsing performance is highly valued in the chemical industry.

Features

- Pressure tight and airtight decanter suitable for toxic or volatile material treatment

- Efficient cake rinsing in the filtration zone

- The tough screw conveyor and the high torque gearbox

- Unique beach structure and a low cake moisture rate

- The gearbox oil circulation system enhances decanter performance and a gearbox life. The forced lubrication system secures gearbox performance in continuous heavy-duty operation.