BDF Decanter

Giá bán: Liên hệ

Hãng sản xuất: Tomoe Vietnam

Danh mục: Thiết bị đo lường & Kiểm tra

Nhà cung cấp: Anh Nghi Son

Xuất sứ:

Bảo hành: 12

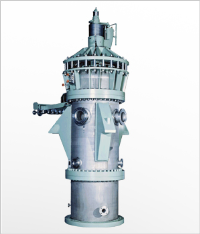

High Performance Thickener

Minimum Flocculation requirement

Description

A large number of BDF Decanter installations prove its various advantages: small footprint, high-capacity, easy maintenance and no-odor emission.

In order to achieve a consistent low return-sludge rate in the supernatant treatment process, we developed BDF Thickening Centrifuge. It produces a great result with low centrifugal force and a small amount of flocculant.

Features

- More than 95% SS recovery with a small centrifugal force and minimum flocculation

- Removal of phosphorus and odor with inorganic coagulant (polyferric chloride)

- Consistent sludge concentration: Continuous concentration monitoring system and automatic differential speed control

- Heavy duty sintered tungsten carbide tiles: Wear-resistive tiles are mounted on the screw conveyor flight with back-up tiles.

- Automatic cleaning-in-place system: Residue cleaning in the shutdown process and the screw conveyor rinsing in the stationary mode

- Power regeneration and energy saving: Recovery of electric energy from the backdrive motor