Grinder with Rotating Screen

Giá bán: Liên hệ

Hãng sản xuất: Tomoe Vietnam

Danh mục: Thiết bị đo lường & Kiểm tra

Nhà cung cấp: Anh Nghi Son

Xuất sứ:

Bảo hành: 12

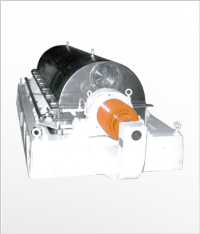

These grinders are equipped with rotating screens. Pressure drop is kept at a minimum, allowing their stable operation at large treatment plants.

Description

A rotating screen (made of SUS or resin) is mounted to a dual shaft grinder, and screenings are trapped by the rotating screen, induced into the grinder, and shredded. As the screen itself rotates, the screenings trapped on the surface of the screen are fed efficiently to the grinder. Screen mesh size is 6.4mm when made of SUS and 15 mm x 18 mm when made of resin.

Features

- Power consumption can be suppressed because the grinder main body and the rotating screen can be driven by one power.

- As the screen itself rotates, when the screen rotates to the downstream side, it is backwashed by influent water. Therefore there occurs little adhesion of screenings to the screen. This makes regular cleaning unnecessary and the maintenance easy.

- There are two types of rotating drum screen; single drum type and double drum type so that they can cater to the needs of both large and small treatment plants. The pressure drop of a double drum type grinder can be decreased significantly, compared to a conventional grinder without a screen.