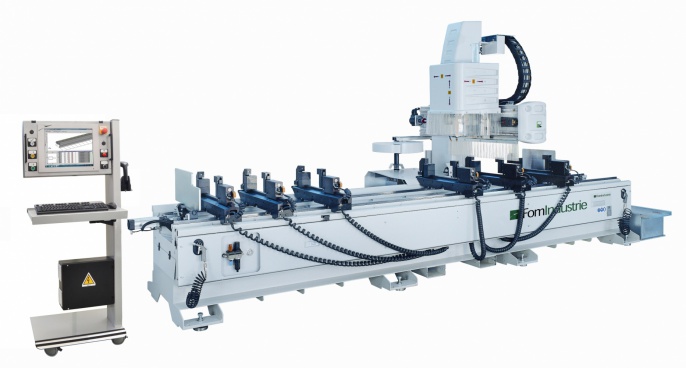

ADIR C

Giá bán: Liên hệ

Hãng sản xuất: Fom Industrie

Danh mục: Máy móc & Hệ thống

Nhà cung cấp: Anh Nghi Son

Xuất sứ:

Bảo hành: 12

CNC Machining Centre with 3 controlled axes and worktable with pneumatic positioning -90°/0°/+90°

Standard accessories of the machining centre:

-

Servo-ventilated three-phase spindle motor 3kW Regulation of spindle rpm by numerical control – inverter (1000/12000 rpm)

-

6 position tool-holder for manual change with pneumatic locking (ISO 30)

-

Pneumatic rotation of the worktable -90° to 0 to +90°

-

Adjustable console with PC, Touch screen 15” keyboard and mouse

-

N° 4 pneumatic vices with manual positioning and double pressure with safety valves

-

MANUALLY ADJUSTABLE Profile reference stops on right and left of worktable

-

Microdrop lubrication with pure oil

-

Chip bin

-

Perimetric guard on 3 sides and front raceding guard

-

Electronic equipment “Tex Computer”

-

Software licence for FOMCAM program

-

FOMCAM training course (FOM premises)