ReVap cuts CO2 production costs by 30% - Union

Giá bán: Liên hệ

Hãng sản xuất: union

Danh mục: Thiết bị trong dây chuyền sản xuất

Nhà cung cấp: Anh Nghi Son

Xuất sứ:

Bảo hành: 0

Save 26%* of a brewery’s total annual CO2 production costs - with an ROI below 12 month

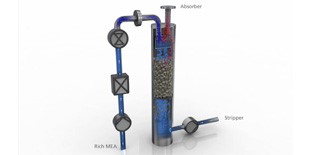

ReVap is a technology designed to minimise both CO2 evaporation and glycol refrigeration expenses in the process.

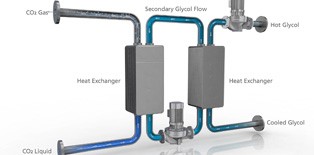

Evaporating CO2 for consumption has always been an unavoidable expense in breweries (and many other CO2 consuming industries), and the same applies to refrigerating glycol. However, by combining these two discrete processes, ReVap reduces the energy costs associated with both.

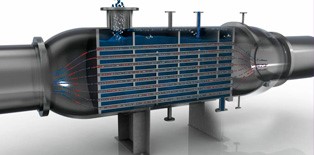

The innovative heat exchange system, ReVap, uses the cooling capacity of stored liquid CO2 to chill glycol. The transfer of heat between glycol and liquid CO2 subsequently raises the temperature of CO2 to its evaporation point. The CO2 is now available for the consumer as gas.

Since the simple concept relies solely on the efficient reuse of existing resources, the ReVap solution offers a saving equivalent to about 26%* of a brewery’s total annual CO2 production costs. A unit typically pays for itself within 12 months.

As a self-contained system, ReVap is installed quickly (within 48 hours) without the need to halt production and its straightforward design makes it virtually maintenance free.

If you are looking to reduce energy bills and increase your positive impact on the environment, ReVap can help.

• Plug & Play – 100 %stand-alone unit, connect piping and wires and run unit

• Reduces CO2 production costs by an average of more than 26% in breweries*

• Free-up refrigeration capacity

• ROI below approx. 12 months

• Can be installed without halting production (i.e. no downtime)

• Virtually maintenance free

• Efficient reuse of existing resources

• Emphasizes the use of ecological and financially sustainable processes and procedures

* based on 35oC cooling water, -40oC glycol, COP = 3 main ref. plant, steam = 22 €/ton, power = 0.1 €/kWh