CO2 recovery in a whole new dimension - Union

Giá bán: Liên hệ

Hãng sản xuất: union

Danh mục: Máy móc & Hệ thống

Nhà cung cấp: Anh Nghi Son

Xuất sứ:

Bảo hành: 0

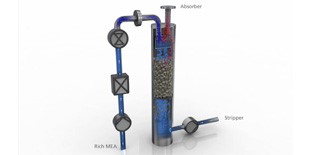

ECO2Brew is a groundbreaking new technology. It is specially designed to recover CO2 from the fermentation processes at breweries and to provide flexibility and savings in a whole new dimension.

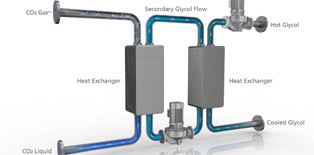

100% water free

Through water-free scrubbing, filtration and separation technology the recovered CO2 is purified to comply with the highest quality requirements in the market. The water-free patented scrubbing technology was developed by Union Engineering a few years back and used in several plants, i.e. distilleries.

However, the rising focus on reduced carbon footprint and water and power savings gave inspiration to transfer the technology to the brewing segment. The technology has proven its value.

Being 100% water free leads to savings of approximately 4.600 m3 drinking water per year for a 1000 kg/h plant.

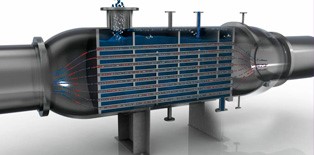

Non-stop efficiency

Another advantage is the reduced power consumption of no less than 20%. This is achieved by using the central refrigeration plant with higher COP-factor, and by using 3-stage floating controlled direct-drive compressors. It increases the efficiency for each compressor, takes advantage of floating fermenter pressure and avoids costly start/stop and relief operation.

Higher recovery rate

Last but not least, the ECO2Brew plants ensure a higher recovery rate. The increased amount of CO2 is obtained due to the recovery at lower raw gas purity and to the highly atomized process, offering the possibility to use the extra CO2 in soft drink or to sell to third part.