Advanced Amine Technology - Union

Giá bán: Liên hệ

Hãng sản xuất: union

Danh mục: Máy móc & Hệ thống

Nhà cung cấp: Anh Nghi Son

Xuất sứ:

Bảo hành: 0

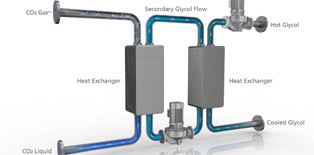

With CO2 Capture plants carbon dioxide can be captured from any gas stream based on the combustion of fossil fuels, including but not limited to coal, heavy fuel oil fired steam boilers, and natural gas-fired combustion engines.

The most well proven absorption technology

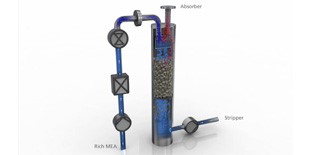

The capture plants from Union Engineering are based on the most well proven absorption technology currently available on the market: High concentrated monoethanolamine (MEA). MEA is a primary amine that reacts readily with carbon dioxide.

Once the carbon dioxide is captured in the MEA solution, it is transferred to a stripping system. Here it is again released from the MEA solution by increasing the temperature to a point where the chemical reaction that took place in the absorber is reversed.

Having started as a gas with a low concentration of carbon dioxide, the gas being released from the stripper is now a highly concentrated stream containing roughly 99% pure carbon dioxide. This stream can either be used directly in gaseous form or be further purified and liquefied to meet the strictest requirements.

Purification column is the final purification step, consisting of a distillation column, which enables separation/blow-off of non-condensable gasses, reducing the O2 content in the final product to max 5 ppm (v/v) and obtaining CO2 purity of min. 99.99% (v/v).

Simple and trouble-free operation

The electrical system for the CO2 generating plants assures:

- The latest PLC technology for operation and monitoring

- Automatic start sequence and fully automatic operation

- Reduced installation and commissioning time on site

The plant is designed for high efficiency and reliability through components selected for 24/7 operation.