CO2 self-generating plants - Union

Giá bán: Liên hệ

Hãng sản xuất: union

Danh mục: Máy móc & Hệ thống

Nhà cung cấp: Anh Nghi Son

Xuất sứ:

Bảo hành: 0

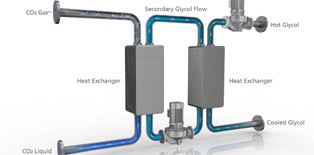

CO2 generating plants (CBU) are based on combustion of fossil fuels such as diesel oil, heavy fuel oil, kerosene, natural gas, LPG or LNG.

Through combustion, scrubbing, absorption, stripping, adsorption and separation technology, the CO2 generating plants meet the strictest CO2 quality requirements regardless of the fuel type.

Life long performance

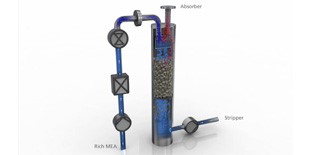

Generating Plants are based on absorption of CO2 from flue gas into a monoethanolamine (MEA) based solution, which is heated by the steam- heated re-boiler to release the raw CO2 gas.

To achieve the best combination of performance and equipment longevity, a 9% MEA /water solution is used. Under this condition, the optimal balance between CO2 load and avoidance of the corrosive effects of MEA are met.

Result-driven technology – NOxFlash and PUR-D

All Union generating plants are based for amine plants, including NOxFlash and PUR-D.

The NOxFlash technology is the result of innovative and research and has been proven in our installations since 2006. The NOxFlash technology:

- Replaces the traditional use of scrubbing with PPM (potassium permanganate) solution, reducing cost and environmental impact.

- Acts as proven abatement of benzene (aromatic hydrocarbons) in the final product.

The PUR-D technology is the final purification step, consisting of a distillation column, which enables separation/blow-off of non-condensable gasses, reducing the O2 content in the final product to max 5 ppm (v/v) and obtaining CO2 purity of min. 99.99% (v/v).

Simple and trouble-free operation

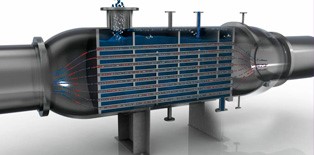

The electrical system for the Generating plants assures:

- The latest PLC technology for operation and monitoring

- Automatic start sequence and fully automatic operation

- Reduced installation and commissioning time on site

All plants are designed for high efficiency and reliability through components selected for 24/7 operation.