Bộ hiển thị Digital indicator COP90 BCS Italy Vietnam - ANS Vietnam

Giá bán: Liên hệ

Hãng sản xuất: BCS Italy VietNam

Danh mục: Thiết bị trong dây chuyền sản xuất

Nhà cung cấp: Anh Nghi Son Vietnam

Xuất sứ:

Ứng dụng sản phẩm: Automotive, Power - Plant, Transpotation

Bộ hiển thị Digital indicator COP90 BCS Italy Vietnam - ANS Vietnam | BCS Italy Vietnam | Đại lý BCS Italy Vietnam

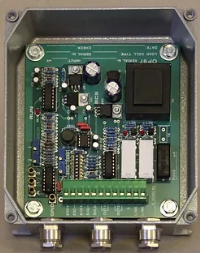

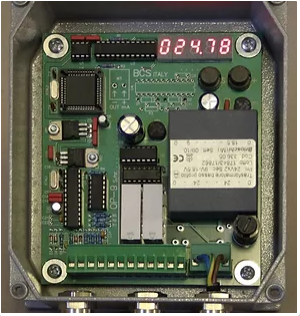

The BCS microprocessor-based COP90 board is a modular apparatus, specifically designed for the load monitoring on cranes.

Up to six independent input channels are available, each one with a power supply unit (10 V DC, 120 mA), amplifier and A/D converter of signal of connected transducer (e.g. load or pressure cells, inclinometers, rope length meters).

The analog-to-digital conversion of the input signal is effected by a dual-slope A/D converter; the instrument is a ratio meter, using the transducer supply voltage as reference voltage, so compensating any error due to voltage drops along the connecting cable, which makes the instrument suitable also for electronic weighing applications, besides the basic overload protection.

The input channels are connected to the motherboard via data bus; they are continuously scanned by an 8-bit CHMOS microprocessor (different chips are used, depending on system configuration), programmed with a suitable software.

Up to 15 SPST output relays are available for alarms and/or commands (16 more with expansion board); a further alarm (fail-safe) is dedicated to detection of apparatus or transducers failure, monitored by means of diagnostic devices.

Up to 8 external commands (e.g., for tare suppression or hoist selection) can be received, via optocoupled inputs.

Analog and/or digital outputs are available, for interfacing with external devices, such as remote repeaters, analog indicators, printers, computers, PLCs, data acquisition systems, and so on.

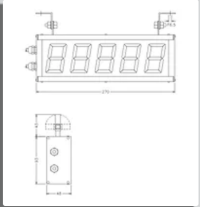

The measured and processed values are displayed through two 7 segments LED displays, plus a 20 dots bar-graph.

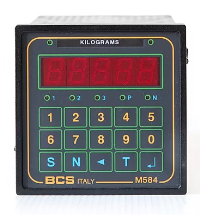

Commands and parameter settings are performed through the front waterproof polycarbonate keyboard, with 16 numeric and function keys.

The compactness of this apparatus allows the installation in a 19" 3 HE standard rack mounting, or in small metal cabinets.

The typical application fields of COP90 board are:

- Overload protection and weighing systems for portainer and transtainer cranes, with monitoring of l oad

unbalance

- Overload protection and weighing systems for jib cranes with multiple hoist, with monitoring of radius and

computation of maximum admissible load

The operational flexibility due to the modular concept allows the application of this apparatus also for other purposes, such as multi-point batching, or weighing of structures, with detection of the center of gravity coordinates.

A) INPUT CHANNEL

Power supply unit: stabilized, 10 V DC, 120 mA; each channel can energize up to 4 x 350 W load cells, parallel connected

Range span: as required, minimum 5 mV, maximum 5 V DC

Resolution: 4000 internal divisions, reading resolution 2000 divisions, multiplying coefficient: 1, 2, 5

Accuracy: ± (0,05% of reading + 1 bit)

Sensitivity: 2,5 µV / LSD

Reading rate: 12 readings/second

Input impedance: greater than 100 MÛ

Common mode rejection: 90 db

Temperature effect: on zero: 6 ppm/°C; on span: 12 ppm/°C

Zero and calibration: through trimmers

B) GENERAL FEATURE

Display: 2 displays, 6 digits, LED 7 segments, 14 mms high, red; bar-graph, 20 divisions ±10% or 0÷100%)

Parameter setup: through waterproof polycarbonate keyboard, with 16 numeric and function keys

Alarms: up to 15 (16 more available with expansion board), for maximum or minimum load, with SPST output relay (2 A capacity at 110/220 V AC); alarm values and time delay settable through keyboard

Fail Safe device: SPST output relay, 2 A, activated in case of:

* transducer measuring bridge failure

* connecting cable interruption

* A/D converter failure

* microprocessor failure

Digital input: 8 optocoupled inputs

Serial output: RS232C or RS422 or RS485 or 0-20 mA Current Loop

Analog output: isolated output, 0÷10 V, or 0÷20 mA, or 4÷20 mA (maximum load 1000 W); non-isolated output, 0÷10 V

Room temperature: operating 0 ÷ 40 °C; storage -10 ÷ 65 °C

Relative humidity: max. 80%

Line voltage: 115 or 230 Volt ±10% (to be specified), 50/60 cycle consumption: 25 VA max