Pinpoint Carbonator - high efficiency in carbonation - Union

Giá bán: Liên hệ

Hãng sản xuất: union

Danh mục: Thiết bị trong dây chuyền sản xuất

Nhà cung cấp: Anh Nghi Son

Xuất sứ:

Bảo hành: 0

High efficiency in carbonation

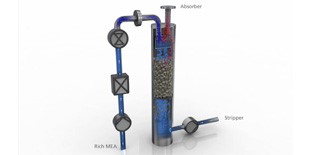

The Pinpoint Carbonator is primarily designed and suited for carbonation of beer, water, soda, wine, and other qualifying liquids but also used for nitrogen injection and wort aeration. The product portfolio has a full range of available capacities (see technical specifiation). Smallest, model 1 inch (Size 25), ideally suited for craft breweries, microbreweries, small wineries and other small operations with low flw applications.

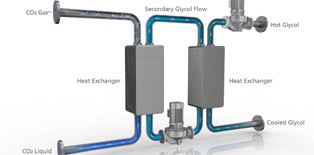

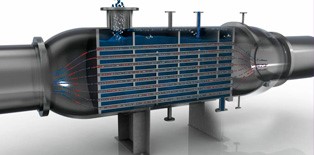

The Pinpoint Carbonator is designed for highest CO2 saturation, and intimate gas-to-liquid bonding with micro-pore, stainless steel injector plates dispersing very fie, 5 – 9 micron size bubbles.

The injector plates in the Wittemann Pinpoint Carbonator are micro porous and feature large contact on both sides. Beer passes across the plates as a thin liquid fim, immediately receiving full CO2 saturation even at the lowest possible flw rate. The foam head remains stable over long time periods; when the head does recede, CO2 saturation continues to hold at a high level.

The immediate saturation and improved bond¬ing provided by pinpoint carbonation reduce foaming during the transfer of beer from Ruh to storage and greatly reduce the beer’s air content. Residual CO2 is used for carbonation from Ruh stage to 2.75 volumes - or, depend¬ing on flw requirements, up to 3.0 volumes - in one pass-through.

For automation of carbonation please see product sheet “Automated Carbonation”

Carbonator benefits:

• Designed for highest CO2 saturation

• The product portfolio has a full range of available capacities

• Simple in-line installation, in either vertical or horizontal line runs.

• Stainless steel construction

• Fully suited for CIP cleaning (solutioning-in-line) or cleaning by use of a ball brush when unit removed from line and replaced with a spool piece.

• Easy access to internal components (porous discs and check valves).

• Lowest pressure drop of any in-line or similar carbonating device

• No longer collapsed foam issues