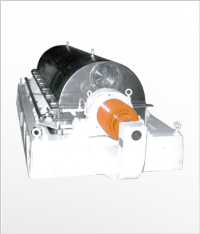

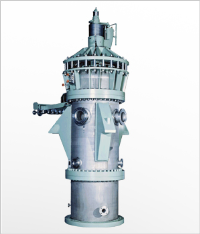

In-Line Grinder

Giá bán: Liên hệ

Hãng sản xuất: Tomoe Vietnam

Danh mục: Thiết bị đo lường & Kiểm tra

Nhà cung cấp: Anh Nghi Son

Xuất sứ:

Bảo hành: 12

These grinders are dual shafted grinders designed for in-line installation. They are standard items with excellent maintenability, and have been installed in a number of water treatment and sludge treatment systems.

Description

Features

- They are dual-shafted grinders. Debris is ground efficiently by a number of cutters installed on the drive shaft and the driven shaft rotating at different speeds.

- The cutters are made of highly wear-resistant special steel so that they can be used for a long time. Cutters made of SUS can be used as well.

- We have a pipe-size line up from 100A to 450A and can respond even to a large throughput capacity requirement.

- They have a structure such that the grinding part can be detached without removing the pipe connection, allowing easy maintenance.