CO2 Recovery plants for breweries - Union

Giá bán: Liên hệ

Hãng sản xuất: union

Danh mục: Máy móc & Hệ thống

Nhà cung cấp: Anh Nghi Son

Xuất sứ:

Bảo hành: 0

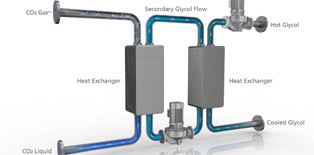

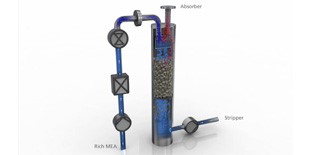

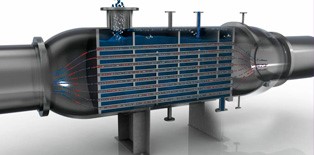

The CO2 Recovery Plants from Union are specifically designed to recover CO2 from the fermentation processes at breweries. Through appropriate scrubbing, filtration and separation technology the recovered CO2 is purified to comply with the highest quality requirements in the market.

The use of structured packing material in the water scrubber reduces the water consumption to 0.25 kg water/ kg CO2. This equals up to 75% reduction compared with traditional plants.

The PUR-D technology is the final purification step, consisting of a distillation column, which enables separation/blow-off of non-condensable gasses, reducing the O2 content in the final product to max 5 ppm (v/v) and obtaining CO2 purity of min. 99.99% (v/v).

Simple and trouble-free operation

The electrical system for the CO2 generating plants assures:

- The latest PLC technology for operation and monitoring

- Automatic start sequence and fully automatic operation

- Reduced installation and commissioning time on site

The plants is designed for high efficiency and reliability through components selected for 24/7 operation.